|

USC Async1 Chip - 1.45 GHz 64-bit Asynchronous Adder |

|

|

1

General Description

The

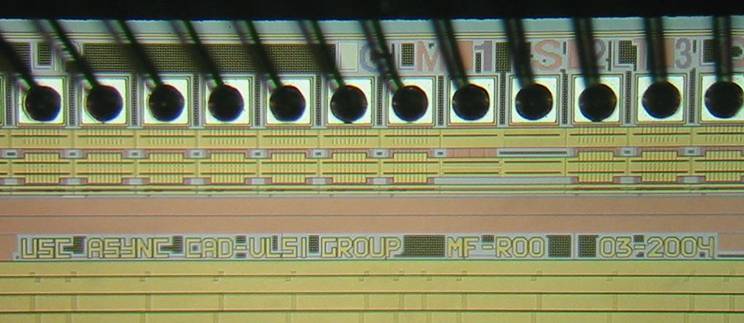

USC Async1 chip was fabricated in March 2004 using TSMC 0.25

um

process. It comprises two test circuits:

§

A 64-bit asynchronous prefix adder with input

generator and output sampler blocks. All blocks were

fabricated to show the high performance of the proposed

STFB (Single-Track Full-Buffer) standard cell design,

which provides low latency and fast cycle time.

§

A Sequential Decoder implemented with QDI

(Quasi-Delay Insensitive) standard cells (this circuit is

under test).

2

STFB template

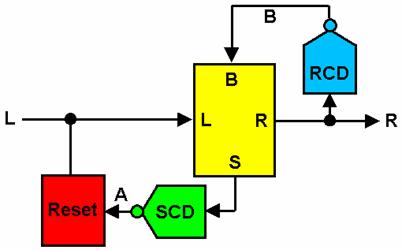

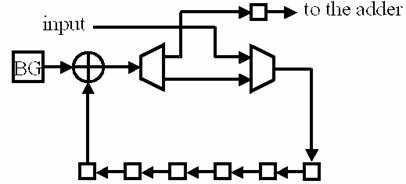

In

the STFB cell template, shown below, the Right Completion

Detection circuit (RCD) allows the cell to work only

if the output channel (R) is empty, and the State

Completion Detector circuit (SCD) removes the input

data from the input channel (L) when it is no longer

needed.

Basic

internal diagram of a STFB cell. |

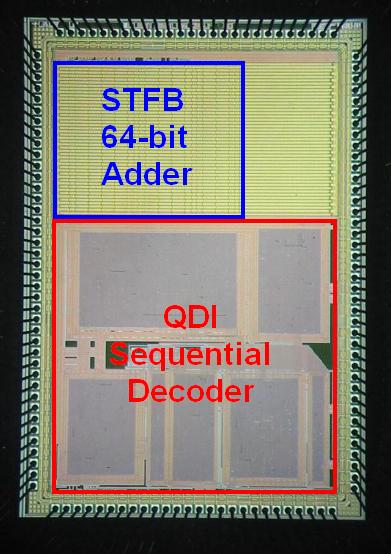

Async1

die photo (bigger

picture). |

|

3

STFB standard cell library

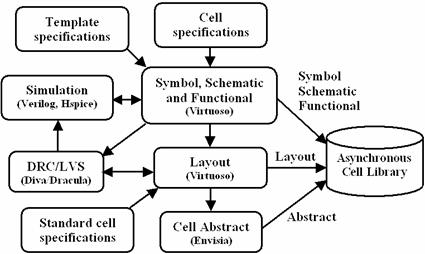

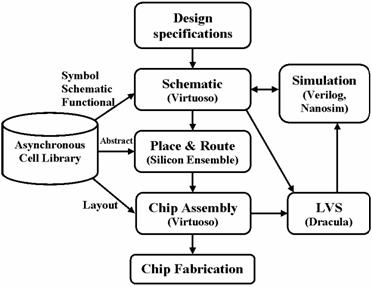

The

STFB cells were created using Cadence Custom IC Design and

Synopsys tools (see

publications below), and were made freely available

through

MOSIS Educational Program. The figure below illustrates

the library creation process.

|

4

STFB block design

Using

the STFB library, the circuit blocks described below were

designed as follows:

|

|

5

INPUTGEN block

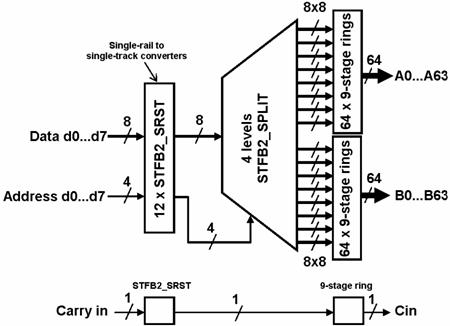

With the

STFB library, the input pattern generator for the adder was

designed as shown in the block diagram below. The INPUTGEN

circuit allows 64-bit operands and 1-bit carries to be

loaded to 9-stage rings that will continuously feed the

adder inputs.

|

6

The

9-stage ring

The

INPUTGEN block has 129 rings with 9-stages each (9 STFB

cells in a loop) as show in the block diagram below. These

rings can load up to 7 different bits that will be

continuously duplicated and send to the adder inputs. All

the 129 rings allow us to load the up to 7 sets of numbers

we want to add (each set with 64-bit for each A operand,

64-bit for each B operand and 1-bit for each carry in).

|

|

7

ADDER64 block

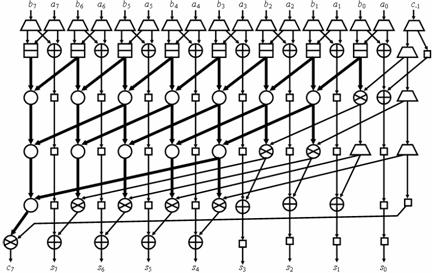

The

figure below represents an 8-bit prefix adder implemented

with STFB cells. The thin arrows are dual-rail channels (2

wires), while the thick arrows are 1-of-3 channels (3

wires). The 64-bit version implemented in our design is an

extension of the diagram below.

|

8

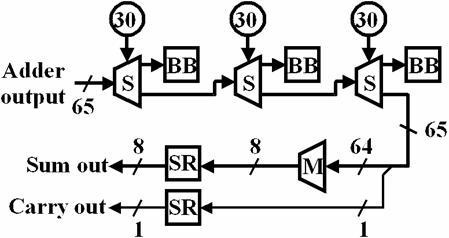

SAMPLER block

Due to the high-performance of the

STFB cells, it is necessary to sample the output results in

order to avoid slow down the adder. The circuit shown in the

diagram below allows us to select the sample rate and also

multiplex the result in order to output one byte at a time.

|

|

9

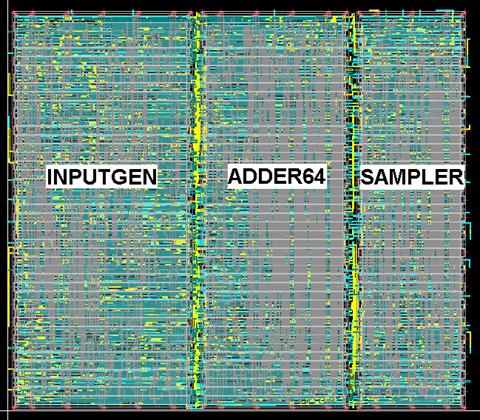

Circuit layout

The

layout of the three blocks were automatically generated and

placed side-by-side as shown below. The three blocks have

260k transistors in 3.3 mm2. The power grid (not

shown) on top of the blocks was designed to supply the high

current required when running at full throughput (28 pads

were allocated for power supply).

|

10

Test board

To

test the chip, an interface board, shown below, has been

designed which connects to an FPGA evaluation board. The

FPGA is a

XILINX XCS2100 Spartan II on a

Xess XSA prototyping board. The software utilized to

program the FPGA was ISE V.6 and the Xess package. Once

programmed, the FPGA loads the STFB INPUTGEN block with the

operands, sets the sample rate in the SAMPLER block, and run

the chip by acknowledging all requests as they come out of

the chip.

|

|

11

Test setup

An

oscilloscope (Tektronix TDS210) was used to check the byte

and carry acknowledge signals. One multimeter was used to

measure the temperature on top of the package (40oC!!),

while another displays the on-chip voltage (2.5V). The

current (2.26A) was measured by the power supply (Agilent

ES610A). A 24-charniel logic analyzer (Link Instruments

LA-2124) was used to capture the waveforms, which allows

checking the initialization and operation of the

demonstration chip. For some clips of the chip performance,

go to the bottom of this page.

|

12

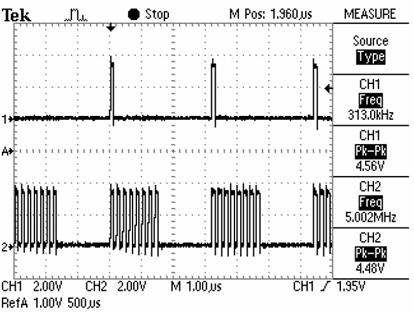

Performance

The

figure below is the acknowledgment signals for the carry and

for the eight bytes outputted by the SAMPLER block. In this

example, since acknowledge frequency was 313kHz and the

sample rate was set to 1:3971, the internal adder throughput

was 1.24GHz. This is an impressive performance

when considering the technology (0.25 um)

and the fact that the layout was automatically generated

using a conventional back-end flow, which resulted in a

simple, fast and efficient design process that can be easily

understood by synchronous designers.

|

|

13

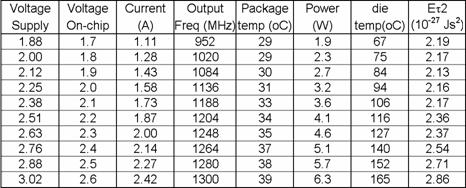

Test results

The

STFB circuits, fabricated in the Async1 chip, worked

perfectly, and generated the expected results (very

close to the Nanosim simulations) reaching up to at 1.45

GHz (with cooling). The following table shows the

results of our tests at room temperature with a fan over the

chip under test.

STFB

circuits at full speed at room temperature with fan.

The

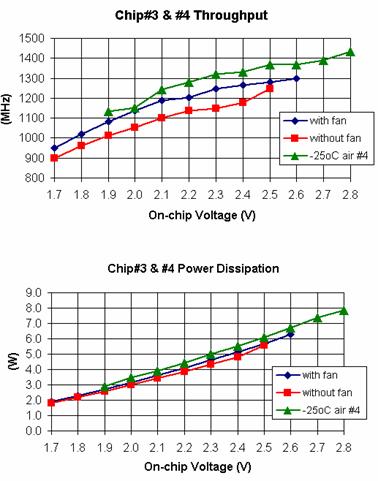

graphics on the right show the throughput and power

dissipation of sample #3 and #4 running at full speed. Chip

#3 was tested at room temperature with and without fan. Chip

#4 was tested with air at -25oC blowing on top of

the device. Notice that, since the STFB circuits are

asynchronous, the performance automatically adjusts

according to the supply voltage and temperature. Also,

notice that, with cooling, the STFB circuits reached the

impressive mark of 1.45 GHz. |

|

|

14

Conclusion

STFB

templates

were

proposed for high-speed area-efficient asynchronous

non-linear pipeline design. A freely available STFB standard

cell library using TSMC 0.25

um

technology was generated and posted with MOSIS Educational

Program. A complete STFB design with 260k transistors

was successfully implemented and tested reaching 1.45 GHz.

The templates have higher throughput

than the fastest known QDI templates and have less timing

assumptions and lower latency than the most aggressive GasP

templates. Consequently, for systems that are

latency-critical, STFB templates may yield a significant

performance advantage. It also offers a small cycle time

that allows the STFB circuits to operate at very high

throughputs with small distances between consecutive data

tokens, resulting in smaller and faster circuits than their

QDI alternatives.

|

15

Publications

For

more information please visit the following links:

-

Thesis:

Single-Track Asynchronous Pipeline Template, Marcos

Ferretti, Ph.D. Thesis, University of Southern California,

Jun, 2004.

-

Papers:

-

Single-Track Asynchronous Pipeline Templates using 1-OF-N

Encoding, M. Ferretti and P. A. Beerel, DATE'02,

Paris, France, March 2002.

- High Performance Asynchronous Design Using

Single-Track Full-Buffer Standard Cells, M. Ferretti and

P.A. Beerel, IEEE Journal of Solid-State Circuits, Vol.

41, No. 6, pp. 1444-1454, June 2006.

-

High Performance Asynchronous ASIC Back-End Design Flow

Using Single-Track Full-Buffer Standard Cells, M.

Ferretti, R.O. Ozdag and P.A. Beerel, 10th Symposium on

Asynchronous Circuits ASYNC, Herssonissos, Greece, April

2004.

|

|

16

Acknowledgements

This

research has been partially supported by NSF Grant

CCR-0086036 and gifts from TRW, Fulcrum Microsystems and the

MOSIS Educational Program. Thanks to Jay Moon for his

valuable help with the CAD tools, to Sachit Chandra for his

help with the design flow and Sunan Tugsinavisut for many

helpful discussions.

Nanosim

and Hspice are trademarks of Synopsys, Inc. (Mountain View,

CA). Dracula, Verilog, Virtuoso, Envisia and Silicon

Ensemble are trademarks of Cadence Design Systems, Inc. (San

Jose, CA). All other trademarks are proprietary of their

respective owners.

|

|